EMI / MFL

|

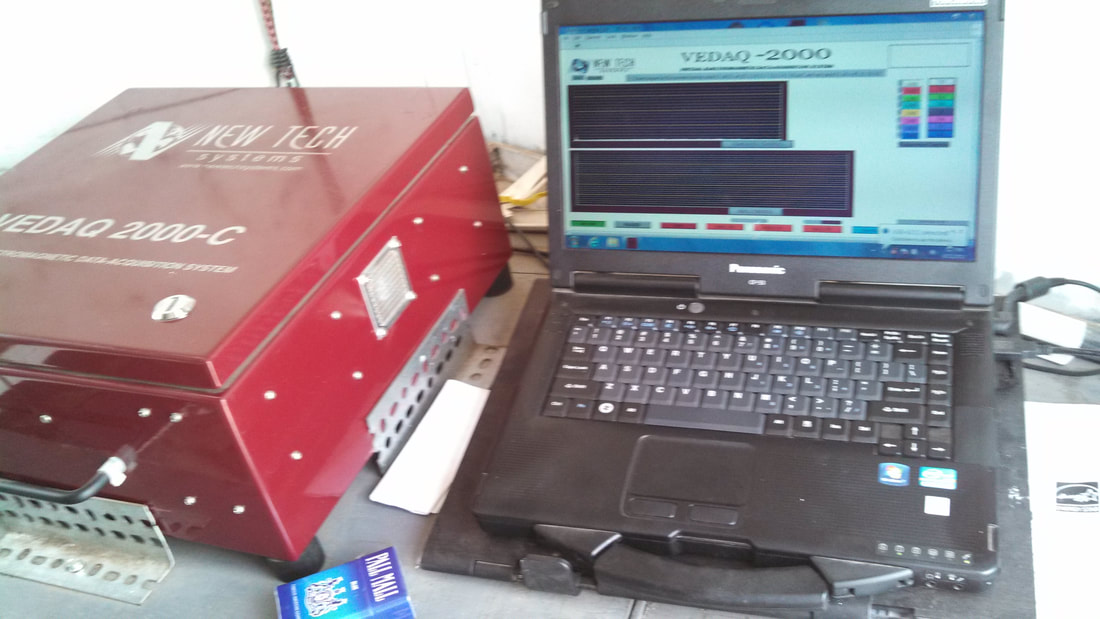

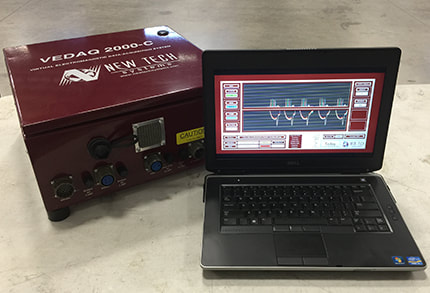

EMI inspection method is an NDT application applied to tubular products such as tubing and drill pipe. It involves full length scanning of tubes using a coil to induce longitudinal field with a buggy type unit to detect transverse flaws in the material, which includes flaws such as fatigue cracks, corrosion, pits, cuts, gouges, and other damage that exceed the specified acceptance limits. If flaws are present, the induced field will create flux leakage at the point of flaw. The leakage is detected by hall effect probes on the buggy witch transmits a signal to a computer console. The signal is then evaluated by a trained inspector. |